PScoat

PowerSmartCoat

Certified Swiss patent for a nanotechnology insulation system. Non-toxic and environmentally friendly product!

Certificates

TECHNOLOGY

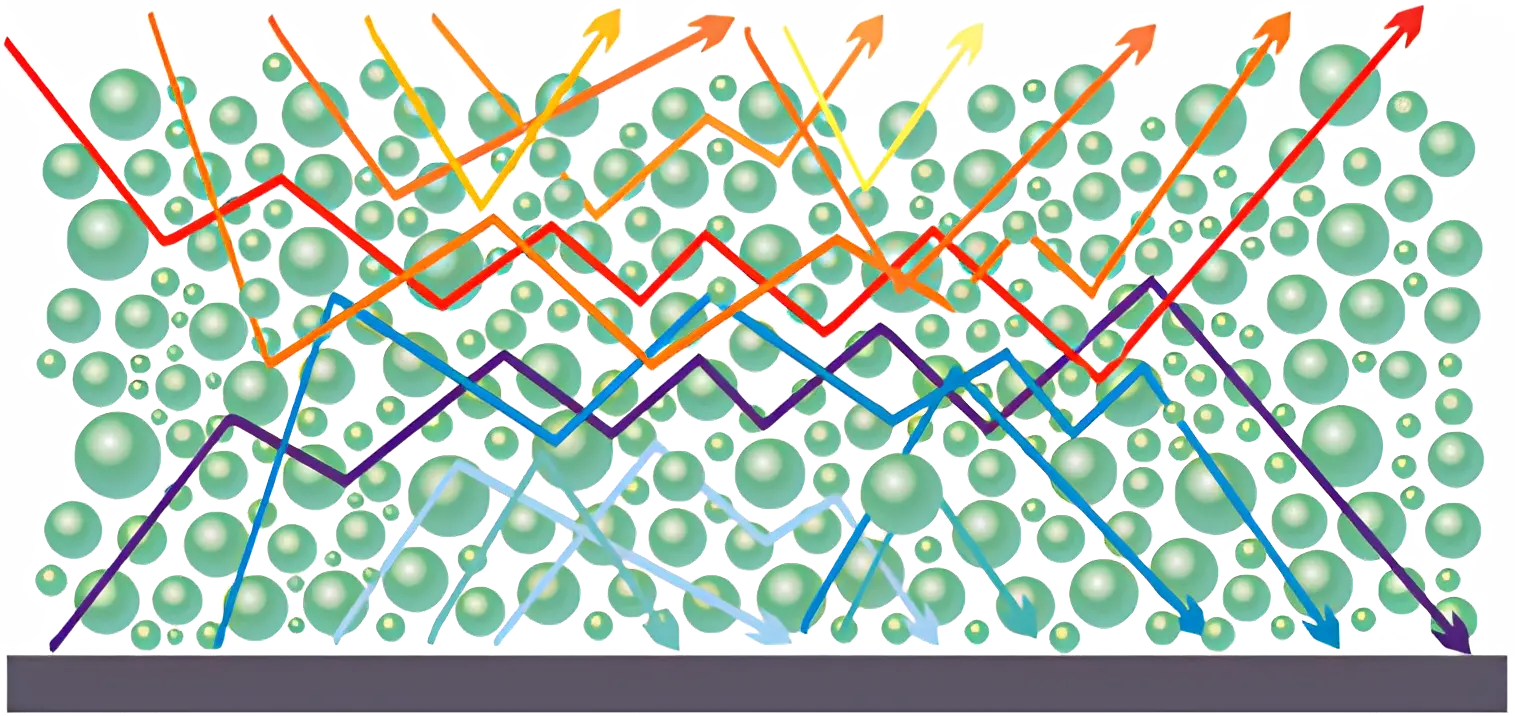

Modern thin-layer insulation technology

- Technology based on nanotechnology and closed microspheres

- A better substitute for polystyrene and mineral wool

- Minimizing heat transfer

- The thickness of the layer is only 1-3 mm

- Space and weight savings, possibility of application in almost any place

- No need to hire a specialized team, simple application by spraying or brushing

- Possibility of visual inspection of the coating condition and quick, spot repair

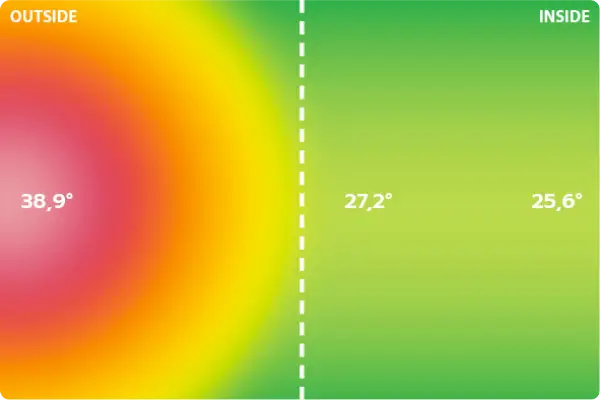

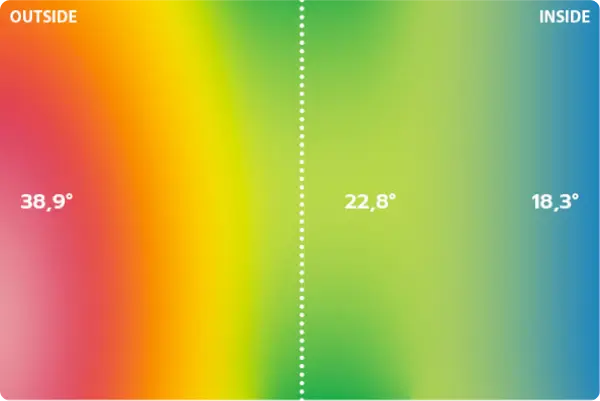

Insulation from heat

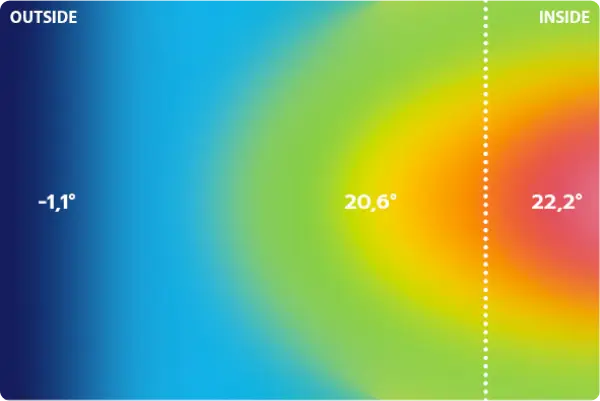

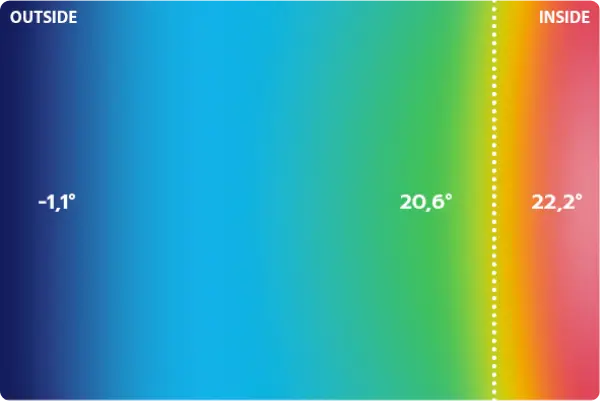

Insulation from cold

PScoat vs Others

Comparison with other insulation materials

Common insulation materialsPScoat

| Attribute | PScoat - Thin-layer insulation | Common insulation materials |

|---|---|---|

| thermal insulation properties | Resistant to temperature fluctuations and air humidity. The thermal insulation provided by PSC is stable in the long term | Due to the moisture contained in the air, the material degrades quickly, thus reducing the life of the insulated installation and its efficiency |

| waterproof | The PSC 250T is moisture resistant as documented by the appropriate certification | The material absorbs moisture from the environment and is not able to prevent corrosion caused by water condensation |

| Corrosion protection | The PSC 250T has anti-corrosion properties - as documented by respective certificate | Cannot solve the corrosion issue |

| Condensation of water | PSC 250T can solve the condensation issue | It cannot solve the condensation issue, possibly only in thick layers |

| UV stable | PSC 250T is UV stable thanks to its TSR properties /Total Solar Reflection - with reflectivity of 92% for all radiation in its entire spectrum/. Solar radiation 97% | Additional protection is required |

| Demands from the point of view of load and occupied space | Thanks to the thin layer of application, mainly between 1-3 mm, the surface is not significantly loaded by the application of PST and due to this thin layer much space around the treated surface is not required | The layer of this insulation takes up much more space and increases its weight, when it gets wet, and so it loads the surface excessively |

| Method of application | Simple and fast application of PSC by spraying or roller. With brush in the case of smaller surfaces | A complex process that requires the use of several sub-components so as to complete the insulation |

| Repairs | Simple identification of defects. Thanks to thin PSC layer the repair are very easy. If a repair is required, the place is cleaned with a brush. The PSC is removed and applied locally after repair completion | Hardly identifiable repairs. No traces of damage can be seen on the insulation surface, but there may be a serious problem with condensation, pests and moulds under insulation. The repairs are demanding and require a complex process of removing the entire insulation and subsequent ecological disposal of the material |

| Service life | As proved by the certificate, expected service life of PCS is 25-30 years | A short service life due to the problem with moisture absorption from the environment or degradation on a very hot surface |

| Resistance against insects, rodents and molds | Thanks to the thin PSC application layer and perfect adhesion to the treated surface, it prevents mould formation and insect movement under insulation. | Insects and rodents can stay under the classical insulation, molds can be easily formed |